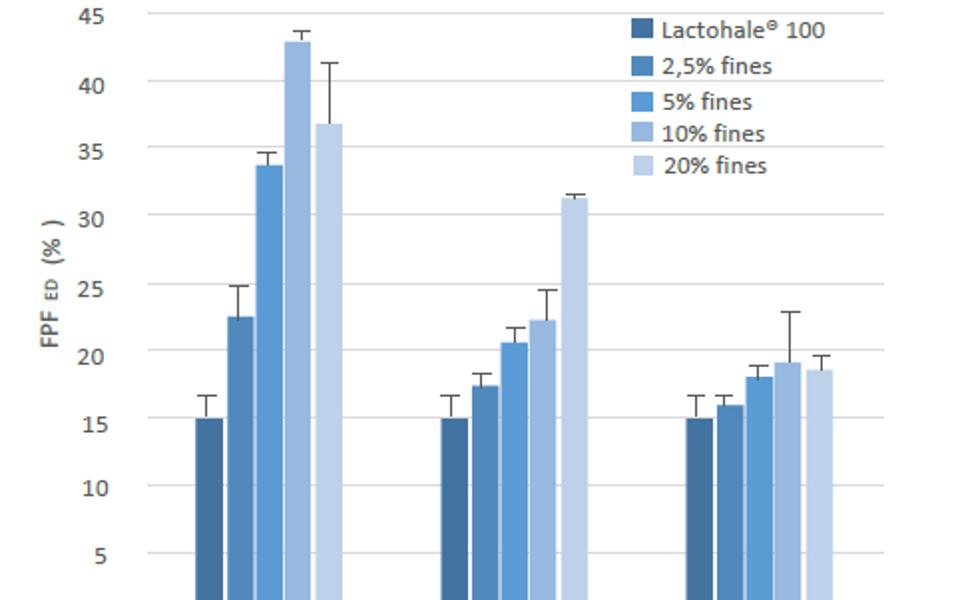

Improved drug deposition

Adding fines to the DPI formulation…

... stimulates drug to occupy the lower energy sites on the surface of the lactose carrier resulting in lower drug-carrier adhesion and improved deposition whereas lactose fines will occupy high energy “active sites”.

Lucas et al. (1998) Pharmaceutical Research 15: 562 - 569.

… supports the formation of drug-fines agglomerates. The agglomerates are exposed to higher drag forces compared to individual drug particles therefore promoting increased detachment from the carrier.

Lucas et al. (1998) Pharmaceutical Research 15: 562 - 569. / Louey et al. (20 02) Pharmaceutical Research 19: 1524 - 1531.

… shelters the drug from high press on forces during mixing, resulting in reduced adhesion between the drug and carrier and thus improved deposition.

Dickhoff et al. ( 2006) International Journal of Pharmaceutics 327; 17-25.

… increases the tensile strength of a bulk powder, as a result the minimum fluidization energy is also increased. The consequence is the formation of larger agglomerates during initial fracture of the bulk powder, which in turn are more easily dispersed leading to an increased fine particle fraction.

Shur et al. (2008) Pharmaceutical Research 25: 1631 - 1640.

Complies with Ph.Eur., USP-NF and JP.

Packaging

- 12,5 kg Cardboard box + Alu liner

Shelf life

12 months

Production site

Borculo, The Netherlands